The expectations placed on tiles have changed dramatically over the years. Today, grout is no anymore viewed as a mere grout between tiles. It is a crucial component to ensure hygiene, durability and aesthetics over the long term. In the end, epoxy grout makers and adhesive sealant producers play a growing part in determining how tile systems perform across commercial, residential, as well as industrial environments.

Epoxy grout is widely used because it’s durable, insensitive to chemicals and is stable even in harsh conditions. Epoxy-based grouts were designed to function consistently in environments where moisture, temperature changes and frequent use can typically cause degradation.

Research and Engineering as the Foundation of Quality

The key to a high-performance epoxy grout is research, not mass production. The manufacturers who put a great emphasis on research and development come up with formulas that balance working ability and long-term endurance. The formulas are designed to flow effortlessly into grout lines that are narrow, while forming an impermeable, solid structure that is impervious to cracking and staining.

Kastar Adhesive Co.,Ltd specialize in the production of adhesives. They offer an One Stop Solution Service that is a part of this research-driven strategy. The company can optimize epoxy grout solutions to meet the demands of real-world applications by integrating the design of products along with manufacturing expertise.

Engineers who have decades of experience in the field analyze the performance and behavior of epoxy grout on various environments, conditions, installation methods and installation methods. This process enables manufacturers to improve formulations that are solid under stress and keep working long after installation.

Precision Manufacturing and Quality Control

It is essential to have consistency in performance for epoxy grout. To maintain exact mixing ratios and cure conditions, the top epoxy grout manufacturers utilize the latest production equipment. This ensures that each batch will have the same characteristics in terms of strength, adhesion and application.

Strict quality control systems are utilized throughout the production process to confirm performance benchmarks. Distributors and contractors alike, this ensures that there are no risks at the job site and eliminates uncertainty when sourcing materials for large-scale projects.

Created to be Multi-Use Across Applications

Epoxy grout developed by experienced adhesive sealant manufacturers is designed to perform across a wide range of applications. It can be used to countertops, floors, and walls as well as outdoor surfaces that are exposed to chemicals and extreme temperatures.

Epoxy grout is perfect for commercial and industrial areas like retail, healthcare, as well as kitchens. It provides an even surface that can be sealed. The ability of epoxy grout to withstand extreme environments makes it a good option for outdoor installations. The traditional grouts typically end up failing over time due to their inability.

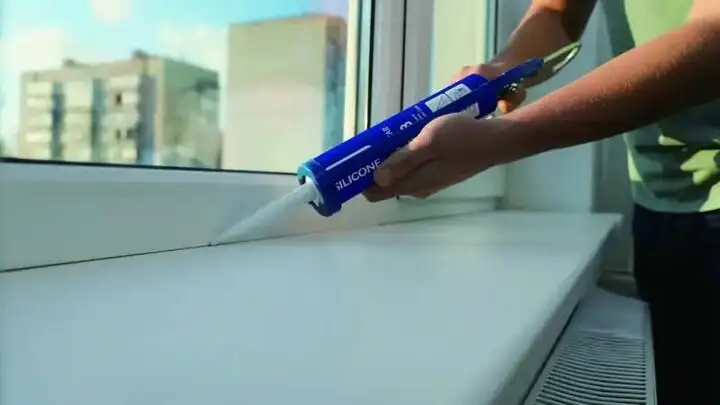

It is important to match the tools and materials.

The efficiency of grout is directly linked to the manner in which it’s applied. The importance of compatibility is recognised by the companies that make epoxy grouts and grouting tools. Installers can get smoother surfaces, greater coverage of joints, and more consistent results when materials and tools cooperate.

The process reduces errors during installation at the site and also reduces waste of materials. For large commercial or wholesale projects, these efficiencies can be directly translated into savings in costs as well as improved timeframes.

We are a wholesale and custom-made grout manufacturer.

Customized grout solutions are popular as construction projects become increasingly special. The top epoxy manufacturers are increasing their ability to develop custom formulations to meet specific needs in terms of performance along with color preferences and environmental conditions.

Kastar’s vast experience in the manufacture of adhesive sealants enables it to provide customized development and large-scale supply. Kastar is able to serve residential, industrial, commercial and retail markets, without compromising on quality or consistency.

The Long-Term Solution to Modern Construction

Epoxy grouts should not be considered to be a temporary solution. When epoxy grout is designed by experienced manufacturers, supported with research, a precise manufacturing and quality control, the product can be considered an investment in performance over the long term.

Epoxy grout is a product which will continue to be used in projects which require long-lasting, reliable and professional outcomes. It ensures that the tile installation is as efficient many years later than they were on the initial day.